Network Servo Interface Adapters for LinuxCNC

This release requires card firmware 3.0.0 or later. Please contact me for update instructions.

Installation - Debian 12 Bookworm (PREEMPT_RT)

- Install Debian 12 Bookworm PREEMPT-RT

- Download and install LinuxCNC 2.9.7nyx55 DEB packages. This build includes the

card driver module and sample configurations

$ sudo apt update

$ sudo apt upgrade

$ sudo apt install wget dkms linux-image-rt-amd64 linux-headers-rt-amd64

$ sudo reboot

$ wget http://yurtaev.com/files/2.9.7nyx55/bookworm-uspace/linuxcnc-uspace_2.9.7nyx55_amd64.deb

$ wget http://yurtaev.com/files/2.9.7nyx55/bookworm-uspace/nyx-pci-dkms_3.2.0_amd64.deb

$ sudo dpkg -i linuxcnc-uspace_2.9.7nyx55_amd64.deb nyx-pci-dkms_3.2.0_amd64.deb

$ sudo apt -f install

$ sudo systemctl stop systemd-timesyncd # disrupts servo-thread period

$ sudo systemctl disable systemd-timesyncd # during system time adjustment

Configuration

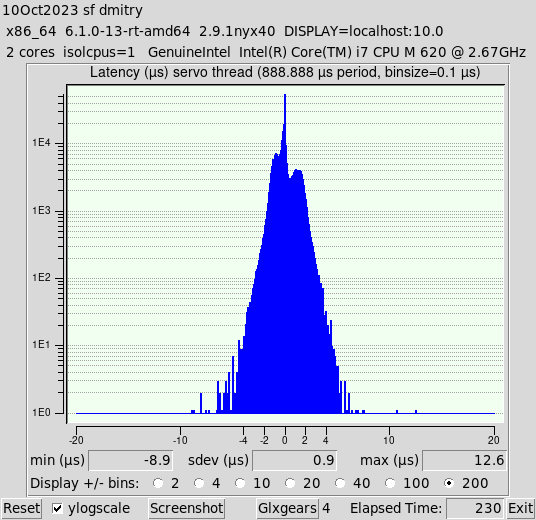

Check realtime latency. Should be somewhere under plus/minus 50us:

$ latency-histogram --nobase --servo 888888

Verify the YxxxxP PCI card has been detected:

$ sudo nyxq info

NYX v3.2.1 YMDS2P -- Oct 4 2023 13:52:35, http://yurtaev.com

axes:9 mds:7 gpi:12+17 gpo:8 enc:6 dac:2 yio:8 stepgen:2

If required, edit ~/linuxcnc/configs/nyx/par/*.par parameter file for your servo drives.

Initially those files contain default parameters which will be transfered to drives

(and will overwrite EEPROM contents on J2/J2S/J3/J4 amps - backup servo drive parameters

using MR Configurator software if you need them)

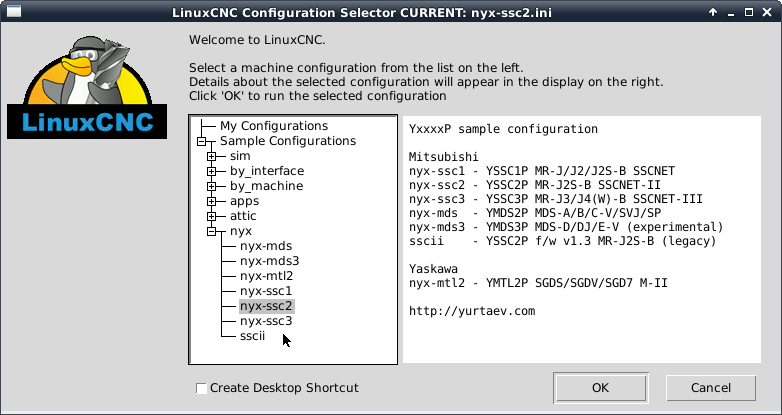

Start LinuxCNC and select sample config matching your card/drives from the tree under "nyx" node.

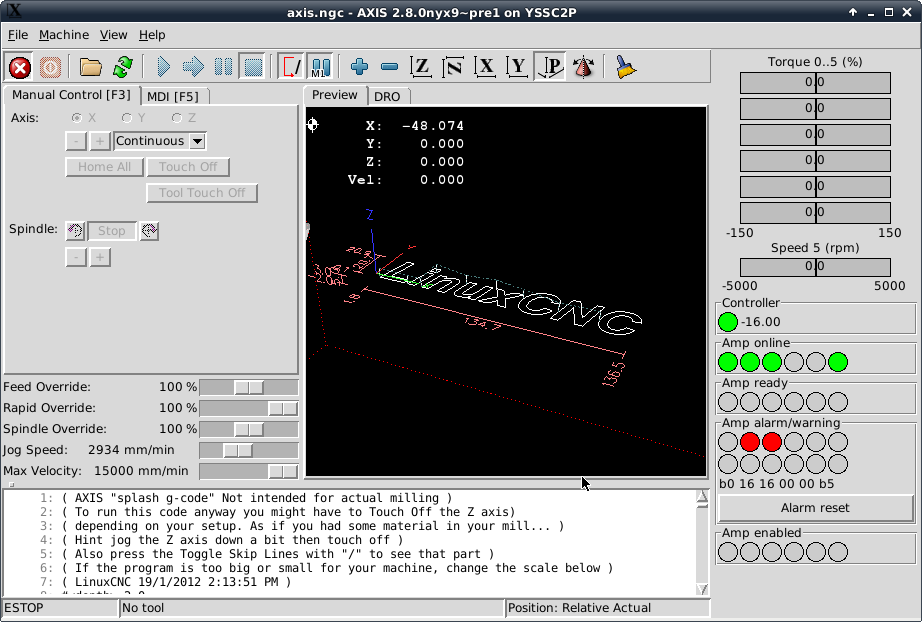

Connected amps should get initialized, corresponding green indicators in the LinuxCNC Axis window should turn on.

LinuxCNC driver v3.2.0 and up

LinuxCNC HAL driver module name is nyx. During operation the

controller and SSCNET network are synchronized to servo thread of the

LinuxCNC. Servo thread period should be set to

- 888888 ns for YSSC1P, YSSC2P, YMDS2P

- 222222 ns for YSSC3P, YSSC3HP, YMDS3P

- 1000000 ns for YMTL1P, YMTL2P

Module parameters:

- maxdrives=N - limit number of axes the module creates pins for

- param_file=PATH - servo parameters file

- nodma=dir - disable DMA PCI transfers, 1=read, 2=write, 3=both. Motherboards with chipsets supporting native PCI usually perform better with nodma=0. With PCIE-to-PCI bridges try nodma=1

- cycle=div - communication cycle divider: 0=servo-thread frequency, 1=1/2, 2=1/4, etc.

- encres=res0,res1,... - feedback resolution override

The following HAL commands load the driver and add its callback function to the servo thread:

loadrt motmod servo_period_nsec=888888 ...

loadrt nyx maxdrives=6 param_file=par/j2s.par

addf nyx.0.rd servo-thread

addf nyx.0.wr servo-thread

servo parameter file

Servo parameters are transfered to drives during initialization after LinuxCNC startup.

Sample files are located in /usr/share/nyx. For MR-J*-B and SGD* parameter file is

optional - drives will use values from the EEPROM. For MDS drives parameter file is mandatory.

Consult servo drive manual for parameters description.

nyx

Controller status pins:

- nyx.0.ready (bit, out) - the controller is in sync with

LinuxCNC servo thread. Before it come true other pins are

inactive

- nyx.0.error-cnt (u32, out) - communication error count. Number

of clocks when servo thread sync was absent. If the value increases then

the jitter is probably too large. Jitter tolerance is about 50

microseconds

- nyx.0.phase (float, out) - an offset of the servo thread call

relative from the timing slot of controller's cycle, 45MHz ticks.

Should not exceed about 1000

servo

Depending on adapter the driver supports up to 16 servo amplifiers, AX number is 00..15. Parameters:

- nyx.0.servo-AX.pos-scale (float, rw) - position scale factor, in length units per revolution. Default is 5, which is suitable for direct motor coupling to 5mm lead ball screw

- nyx.0.servo-AX.vel-scale (bit, rw) - velocity scale factor. Default is 10, so that vel-cmd is in rotation per minute with 0.1 rpm resolution. For J3/J4 should be set to 100

- nyx.0.servo-AX.trq-scale (bit, rw) - torque scale factor. Default is 1

- nyx.0.servo-AX.origin (signed, rw) - position offset

Mechatrolink uses a fraction of max motor speed/torque as units during velocity control, see [NYX] section in nyx-mtl2.ini sample config for sample values.

Pins:

- nyx.0.servo-AX.online (bit, out) - the controller has detected and initialized AX servo amplifier

- nyx.0.servo-AX.offline (bit, out) - inverted online pin output

- nyx.0.servo-AX.ready (bit, out) - READY-ON status (power relay is on)

- nyx.0.servo-AX.enabled (bit, out) - SERVO-ON status

- nyx.0.servo-AX.warning (bit, out) - servo amplifier warning

- nyx.0.servo-AX.alarm (bit, out) - servo amplifier alarm

- nyx.0.servo-AX.alarm-code (u32, out) - servo amplifier alarm code (hex)

- nyx.0.servo-AX.zero-speed (bit, out) - motor velocity is below zero speed threshold (set by amp param)

- nyx.0.servo-AX.in-position (bit, out) - position complete (threshold set by amp param)

- nyx.0.servo-AX.at-speed (bit, out) - motor at reached commanded speed (velocity control mode)

- nyx.0.servo-AX.in-NN (bit, out) - [ssc3/mii] amplifier digital input state, NN is 00..02

- nyx.0.servo-AX.in-NN-not (bit, out) - [ssc3/mii] .. inverted

- nyx.0.servo-AX.out-NN (bit, in) - [ssc3] set servo amplifier digital output selected by 0x21, 0x22, 0x23 in PD07..PD09

- nyx.0.servo-AX.power (bit, in) - turn on amplifier power relay (READY-ON)

- nyx.0.servo-AX.enable (bit, in) - enable servo (SERVO-ON)

- nyx.0.servo-AX.reset-alarm (bit, in) - reset servo amp alarm when true

- nyx.0.servo-AX.pos-cmd (float, in) - position command input

- nyx.0.servo-AX.pos-fb (float, out) - motor feedback position

- nyx.0.servo-AX.velocity-mode (bit, rw) - [ssc2/ssc3/mii] velocity control mode. Change is possible at zero speed only

- nyx.0.servo-AX.vel-cmd (float, in) - [ssc2/ssc3/mii/mds] commanded velocity

- nyx.0.servo-AX.vel-fb (float, out) - motor velocity feedback

- nyx.0.servo-AX.trq-fb (float, out) - motor torque feedback, percent of nominal motor torque

- nyx.0.servo-AX.error-cnt (s32, out) - amplifier feedback receive error count

- nyx.0.servo-AX.spindle-fwd (bit, in) - [mds] start spindle in forward direction with vel-cmd speed. enable should be false

- nyx.0.servo-AX.spindle-rev (bit, in) - [mds] start spindle in reverse direction with vel-cmd speed. enable should be false

- nyx.0.servo-AX.spindle-orient (bit, in) - [mds] start spindle orientation. Has proirity over spindle-fwd, spindle-rev

- nyx.0.servo-AX.spindle-orienting (bit, out) - [mds] spindle orientation in progress

- nyx.0.servo-AX.spindle-oriented (bit, out) - [mds] spindle orientation complete

- nyx.0.servo-AX.spindle-lcoil (bit, in) - [mds] select spindle low-speed coil

- nyx.0.servo-AX.spindle-in-coil-change (bit, out) - [mds] true during coil change

- nyx.0.servo-AX.spindle-in-lcoil (bit, out) - [mds] low-speed spingle coil active

- nyx.0.servo-AX.counts (s32, out) - servo position feedback counts in native encoder resolution

- nyx.0.servo-AX.counts-cmd (s32, out) - servo position command counts in native encoder resolution

- nyx.0.servo-AX.droop (s32, out) - amplifier reported following error, in native encoder resolution

- nyx.0.servo-AX.rxtime (s32, out) - amplifier feedback reception time during servo cycle for servo protocol debug

- nyx.0.servo-AX.forward-torque (float, in) - forward rotation torque limit, percents

- nyx.0.servo-AX.reverse-torque (float, in) - reverse rotation torque limit, percents

- nyx.0.servo-AX.limit-torque (bit, in) - turn on torque limiting

- nyx.0.servo-AX.torque-clamped (bit, out) - torque clamp indication

- nyx.0.servo-AX.absolute (bit, out) - absolute position feedback is valid (set by amp param)

- nyx.0.servo-AX.abs-lost (bit, out) - absolute position is not valid due to e.g. motor disconnection or discharged backup battery

- nyx.0.servo-AX.abs-ok (bit, out) - absolute position is enabled and valid

- nyx.0.servo-AX.index-enable (bit, io) - [ssc3] reset pos-fb to zero on encoder index pulse, for z-index homing

- nyx.0.servo-AX.undroop (bit, in) - connect to joint.x.homing to add droop pulses to pos-fb to avoid jerk during z-index homing

- nyx.0.servo-AX.z-offs (s32, out) - connect to joint.x.homing to add droop pulses to pos-fb to avoid jerk during z-index homing

- nyx.0.servo-AX.z-offs-delay (s32, in) - delay (cycles) when z-offset is available after the z-passed flag is raised

encoder

An encoder input channel converts quadrature signals on CN2 Phase A, Phase B, Index Z into 32-bit up/down counter values. The sampling requency is 45 MHz. NN is

encoder channel: 00 or 01. Parameter:

- nyx.0.encoder-NN.cpr (float, rw) - encoder resolution, counts per revolution. Sign defines rotation direction. Default is -10000

- nyx.0.encoder-NN.x4-mode (bit, rw) - count on every edge

Pins:

- nyx.0.encoder-NN.index-enable (bit, io) - reset counter on next index mark Z

- nyx.0.encoder-NN.pos (float, out) - encoder counter divided by the cpr parameter value. Signed fractional number of revolutions.

- nyx.0.encoder-NN.counts (s32, io) - encoder counter.

- nyx.0.encoder-NN.velocity (float, out) - estimated velocity, RPM.

The interface is intended for use with motion.spindle-index-enable and motion.spindle-revs.

gpio

Digital input signals IN0..IN11 connected to CN1. Pins:

- nyx.0.in-NN (bit, out) - a state of digital input NN 00..11

- nyx.0.in-NN-not (bit, out) - inverted

Expansion connector CN2 as GP inputs IN12..IN29. Pins:

- nyx.0.in-NN (bit, out) - a state of digital input NN 12..29

- nyx.0.in-NN-not (bit, out) - inverted

Digital output signals OUT0..OUT7 going to CN3:

- nyx.0.out-NN (bit, in) - set output number NN 00..07

dac

2-channel 12-bit digital-to-analog converter on YEX1-A expansion board. Paramaters:

- nyx.0.dac-CH.scale (float, rw) - max input value (for 10V output voltage). Default is 1.0, CH is 00 or 01

- nyx.0.dac-CH.bias (float, rw) - DAC offset. output voltage = 10V * (value / scale + bias)

Pins:

- nyx.0.dac-CH.value (float, in) - DAC output voltage, values 0..scale give 0..10V

yio

Connected YIO modules are detected, pins are created for each on nyx module load. ID is by DIP switches, 00..15.

Pins:

- nyx.0.yio-ID.in-NN (bit, out) - a state of digital input NN 00..1f (hexadecimal)

- nyx.0.yio-ID.in-NN-not (bit, out) - a state of digital input NN, inverted 00..1f

- nyx.0.yio-ID.out-NN (bit, in) - set output NN 00..1f

- nyx.0.yio-ID.alarm (bit, out) - true if serial connection to the module is interrupted or fault is reported by the I/O module

- nyx.0.yio-ID.error-cnt (s32, out) - communication error counter

YO32P pins:

- nyx.0.yio-ID.vb1 (float, out) - 00..0f output driver field voltage supply

- nyx.0.yio-ID.vb2 (float, out) - 10..1f output driver field voltage supply

- nyx.0.yio-ID.t1 (float, out) - 00..0f output driver temperature, degrees centigrade

- nyx.0.yio-ID.t2 (float, out) - 10..1f output driver temperature, degrees centigrade

- nyx.0.yio-ID.i-NN (float, out) - digital output NN 00..1f current, mA

- nyx.0.yio-ID.v-NN (float, out) - digital output NN 00..1f voltage, V

- nyx.0.yio-ID.pull-down (bit, in) - disable weak pull-ups on outputs

YAO2 params:

- nyx.0.yio-ID.encoder-NN.cpr (float, rw) - counts per revolution

- nyx.0.yio-ID.encoder-NN.min-speed-estimate (float, rw) - the minimum velocity at it will be reported as nonzero

- nyx.0.yio-ID.encoder-NN.x4-mode (bit, rw) - when true (the default), the counter counts each edge of the quadrature waveform (four counts per full cycle)

YAO2 pins:

- nyx.0.yio-ID.dac-NN.value (float, in) - DAC output voltage, values -scale..scale give -10V..10V

- nyx.0.yio-ID.dac-NN.bias (float, in) - DAC offset. output voltage = 10V * (value / scale + bias)

- nyx.0.yio-ID.dac-NN.scale (float, in)

- nyx.0.yio-ID.encoder-NN.index-enable (bit, io) - encoder Z index enable

- nyx.0.yio-ID.encoder-NN.pos (float, out) - counts / cpr

- nyx.0.yio-ID.encoder-NN.velocity (float, out)

- nyx.0.yio-ID.encoder-NN.velocity-rps (float, out)

- nyx.0.yio-ID.encoder-NN.counts (s32, out)

Absolute encoder support

Motors with absolute encoders allow to skip LinuxCNC homing operation on each startup. Patched version

of LinuxCNC adds the folloing pins to halui module:

- halui.joint.n.set-homed (bit, in) - set axis "homed"

state to true for current offsets without actually performing a homing

operation

Those pins can be connected to

net x-abs-ok halui.joint.0.set-homed <= nyx.0.servo-00.abs-ok

net x-abs-lost halui.joint.0.unhome <= nyx.0.servo-00.abs-lost

To enable absolute encoder mode, set parameters:

- MR-J2(S)-B: No.1=0001

- MR-J3/J4-B: PA03=0001

- MDS-x-V: SV017 bit 7 (0080)

- SGDS: Pn002=_0__

For Yaskawa drives write Pn002 to NVRAM. Start LinuxCNC and execute the following commands (should be in servo-off):

$ sudo nyxq servo pwnv 0-2:Pn002=0x13 # axes 0..2. power cycle amps, will show A.810

$ sudo nyxq servo abs 0 1 2 # execute encoder setup op and power cycle again

Add [JOINT_n]ABSOLUTE_ENCODER=1 var to .ini configuration file. LinuxCNC will save

the motor_offset to the position file instead of current position.

Mitsubishi MDS-x-SP spindle drive sync moves

The mdssp component emulates ABZ incremental encoder using spindle drive postion feedback.

To use it for lathe threading or rigid tapping make sure SP038 bit 2 (0x0004) is set to 1 and make

the following HAL connections:

loadrt mdssp

addf mdssp.0 servo-thread

net s-counts nyx.0.servo-05.counts => mdssp.0.spindle-counts-in

net s-oriented nyx.0.servo-05.spindle-oriented => mdssp.0.spindle-oriented-in

net s-index spindle.0.index-enable => mdssp.0.index-request

net s-revs spindle.0.revs <= mdssp.0.revs

To make emulated spindle index postiion repeatable between LinuxCNC restarts, execute the "orient spindle" op once.

Z-index homing

When using MR-J3-BS or MR-J4-B-RJ amps in fully-closed mode with an ABZ incremental linear/rotary load-side encoder

LinuxCNC's Z-index homing is supported. To use it add to HAL/INI:

net x-home nyx.0.servo-00.di3 => joint.0.home-sw-in

net x-index nyx.0.servo-00.index-enable <=> joint.0.index-enable

net x-homing nyx.0.servo-00.undroop <= joint.0.homing

HOME_USE_INDEX = YES

ABSOLUTE_ENCODER = 0

Z-index homing is also supported with SSCNET III/H and Mechatrolink I, II since fw 3.0.10, MDS-A/B/C-V since 3.4.0

nyxq utility

- Card firmware information

$ sudo nyxq info

NYX v2.4.0 YMDS2P -- Jun 2 2020 20:16:07, http://yurtaev.com

axes:7 mds:7 gpi:12+17 gpo:8 enc:2+4 dac:2 yio:12

Servo information

$ sudo nyxq servo info

SSCNET III 8 axes replied:0 online:1

0: [e9] pos= 2113657638 vel=0.0 trq=0.0 inp wrn

Servo parameters writing/reading

$ sudo nyxq servo pw 0,2:pa9=10

$ sudo nyxq servo pr 0-2:PA9 # works for SSCNET-III and Mechatrolink-II only

0:P9=10 0xa

1:P9=12 0xc

2:P9=10 0xa

I/O monitor

$ sudo nyxq io

ENC0..5: 45656 0 0 0 0 0

DAC0..1: 0 0

------- fedcba9876543210fedcba9876543210

GPI: -11-111-111111111------------

GPO: --------

0: YI16 ----------1--111

1: YO16 ---------------1

2: YI32 -------------------------------1

3: YO32 -------------------------------1

------- fedcba9876543210fedcba9876543210